Polyfruit is the only machine existing in the international market able to extract the juice both from citrus (after the extraction of the essential oil by Polycitrus M6) and tropical fruit (pineapple, passion fruit, papaya, melon, guava and banana).

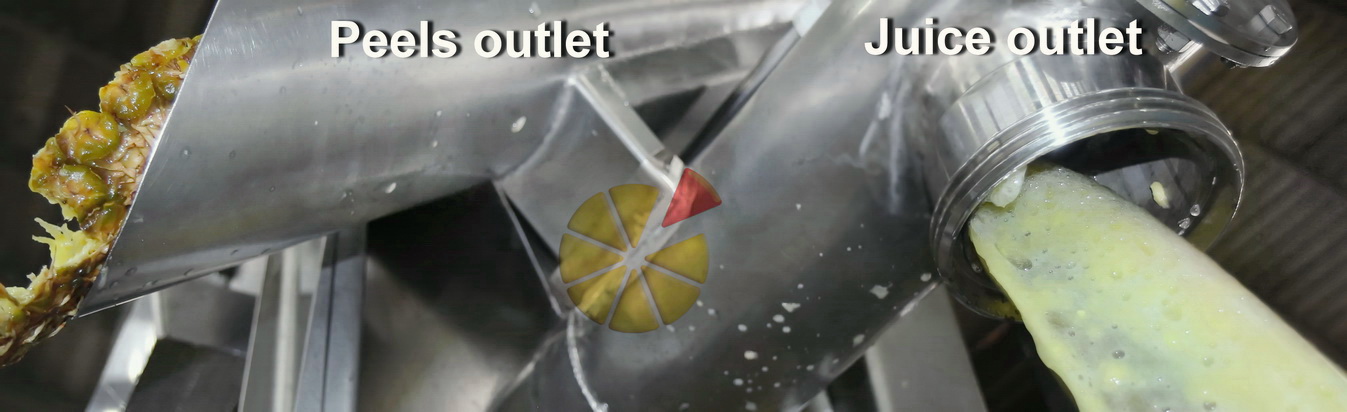

The yelds are higher in quantity and quality than those of any other type of extractor and due to its working principle any contact between peel and juice is minimized.

Polyfruit juice extractor can be configurated in several versions, each of one suits to a specific fruit variety.

The configurations can be easily changed from one to the other fruit by a rapid replacement of some of its components provided as a kit with the extractor.

The operation needs just one operator and about 20 minutes to be completed.

Polyfruit juice extractors are very reliable because of their design and construction, they need low maintenance charges that guarantee them a very long lifetime.

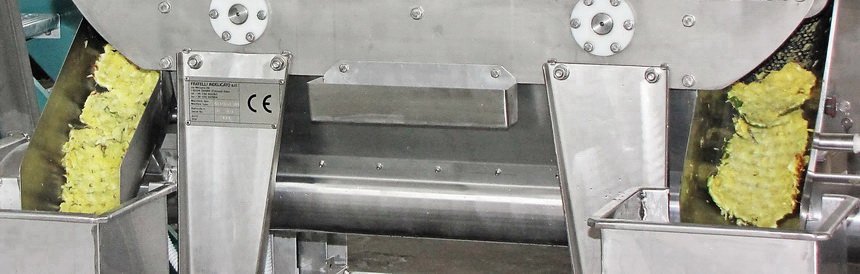

Pineapple juice extraction

Passion fruit juice extraction

Papaya juice extraction

Tropical fruit processing line. Capacity: 4 tons/hour. Obtainable products: tropical fruit juice.

Citrus and tropical fruit integrated processing line. Capacities: 6 tons/hour of oranges, 4 tons/hour of pineapples. Obtainable products: citrus juice and essential oil, tropical fruit juice.